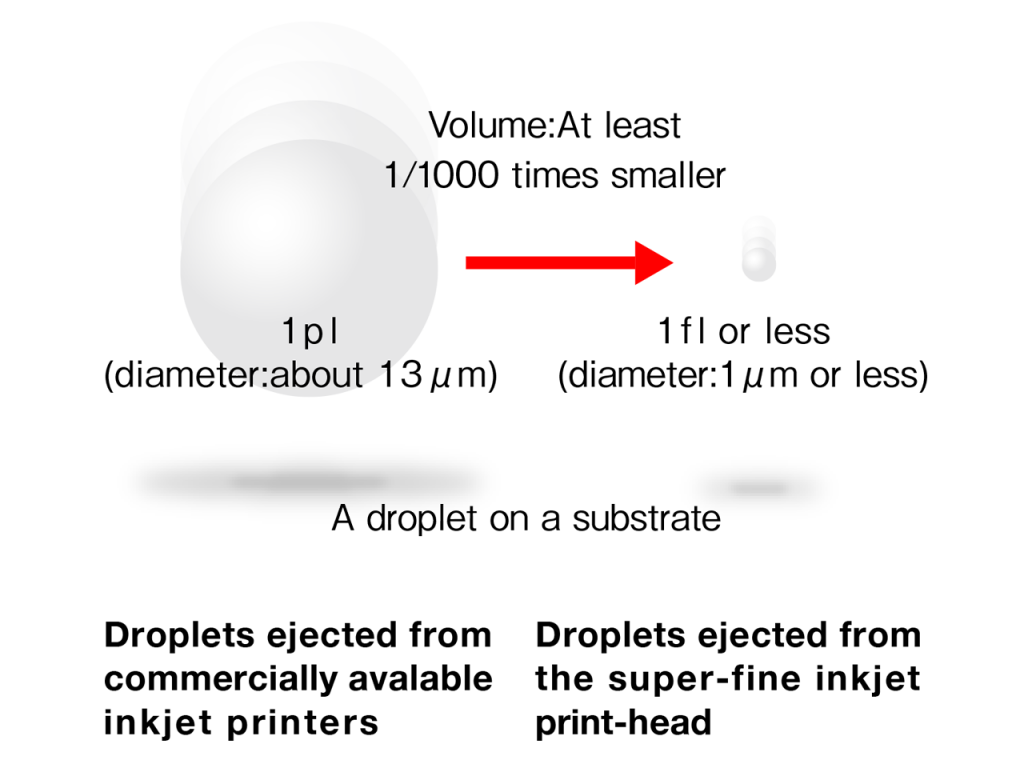

The super-fine inkjet technology developed by the Nanotechnology Research Institute of AIST allows the ejection of super-fine droplets much smaller than the conventional droplets ejected by a conventional inkjet printer-less than 1/10 the size and less than 1/1000 the volume of conventional droplets.

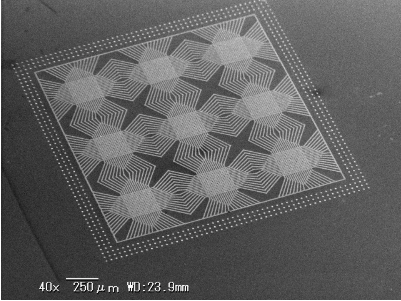

An interesting aspect to metals is that for particles smaller than 20 nm in diameter, the effective melting point decreases dramatically. For example, the melting point of a super-fine silver particle may be as low as room temperature, whereas a micron sized particle of silver melts at 961ºC! Using a solution with these nano-size particles as ink, with out novel printer, enables maskless patterning with a line width of several microns, which is comparable to the photolithographic methods, but at room temperature and normal atmospheric pressure!

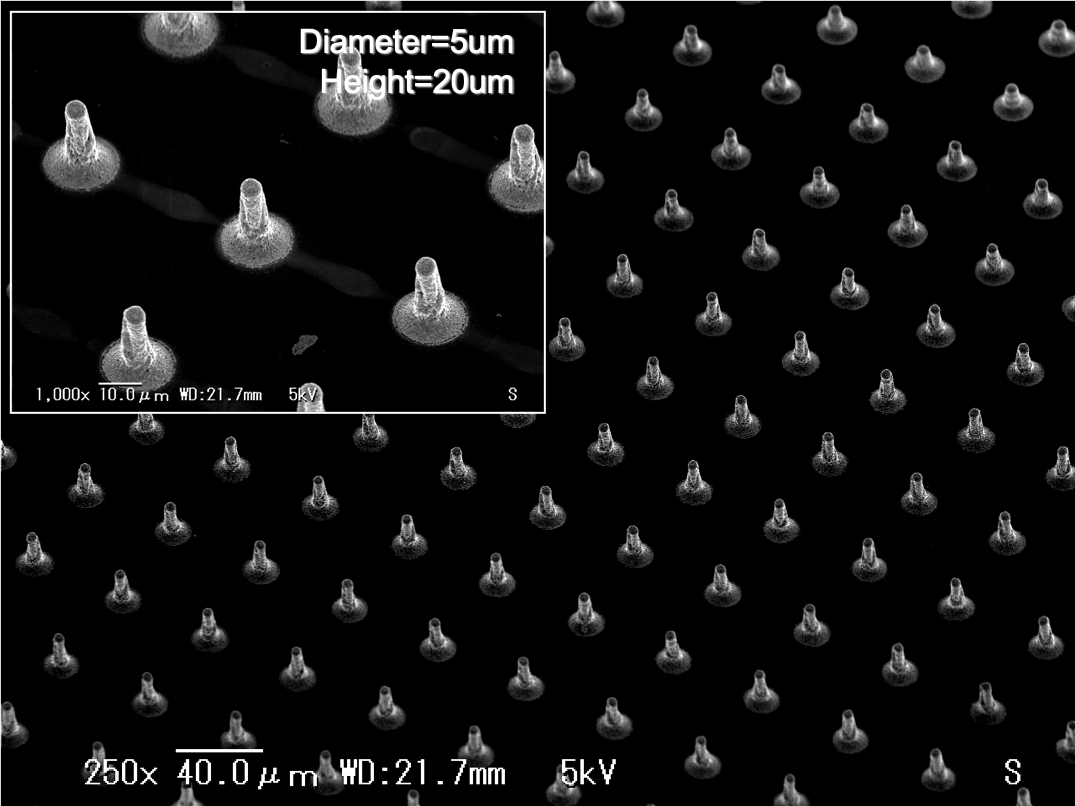

Because super-fine liquid droplets dry very quickly, the droplets can be accumulated to form a three-dimensional structure by shooting them at a fixed target.